12-meter daughter craft operated by North Star

North Star, Daughter craft is used by the offshore wind industry to safely transfer technicians between the in-field Service Operation Vessel (SOV), where they live while working offshore, to the wind turbines to undertake routine or remedial maintenance. They are also used to support trips to shore, and daughter craft provides essential emergency safety and rescue cover.

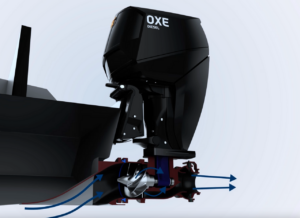

Over the last two years, North Star’s teams in Newcastle, Lowestoft and Aberdeen have closely partnered with Chartwell Marine to produce a world-class high, performance, comfortable and sustainable daughter craft vessel design. It introduces outboard hybrid propulsion into the daughter craft market for the first time, utilising twin OXE 300hp diesel outboards supplied by Proteum in addition to Torqeedo Deep Blue electric outboards, setting a new standard for safe operations with an increased sea state operability at wave heights of up to 1.7m, which is 33% higher than anything else currently in operation.

The vessel also carries green technologies to reduce carbon emissions, and it is configured for further improvements in green technologies as the sector evolves.

The firm’s Renewables Director, Andrew Duncan, said: “The UK has the world’s largest offshore wind market backed by an experienced and innovative supply chain. We are committed to providing local content opportunities through direct and indirect employment, partnerships, and supply chains. Our annual spending is tens of millions of pounds, so we need to feel confident in our investments.

“Our relationship and collaboration with Proteum have ensured that we are bringing a transformational daughter craft design to the industry, using the latest technologies to increase safety, performance, reliability, comfort, while reducing emissions.”

Why outboard instead of inboard?

Outboard engines have many advantages over inboard or sterndrive systems, which you can read more about here (open document). Still, in this instance, the key is that the daughter craft can be maintained and repaired onboard the SOV. Due to the ease of access and removal of the outboard engine, the SOV can carry a complete spare engine. So, if the worst should happen and the engine cannot be repaired, then it can be swapped out in just a few hours, enabling the daughter craft to be back out and working in no time. With an inboard system, the daughter craft would be out of operation until the SOV can come into port, potentially costing thousands, if not tens of thousands of pounds.

Why diesel over petrol?

There are the usual safety factors, but with offshore vessels like this, having a single-use fuel makes operational processes much easier and more efficient. You must only carry one fuel onboard the SOV to service all onboard equipment. Also, torque is critical in these applications; with the weight of the vessels, a petrol outboard couldn’t produce enough torque.

Why OXE?

Torque and thrust are two of the main reasons. The OXE diesel outboard is the only one in the market that can run 17” in diameter, with custom-made 5-blade props. Efficiently and effectively transferring the increased torque that produces the vast thrust required to hold the daughter craft against the pylon and safely transfer the crew.

Three of the initial orders of six daughter craft have already been launched from the Alicat facilities in Great Yarmouth, with the fourth expected to launch during April 2024; for more information on the vessels operated by North Star and the services they provide, please visit: https://www.northstarshipping.co.uk

For more information on the OXE range of diesel outboards, please contact [email protected]